We produce

Stormwater treatment facilities

- Accumulating tanks

- Grit chambers

- Class 1 light liquids separators

- Class 2 light liquids separators

- Active Carbon filters

- TRIPLEX separator

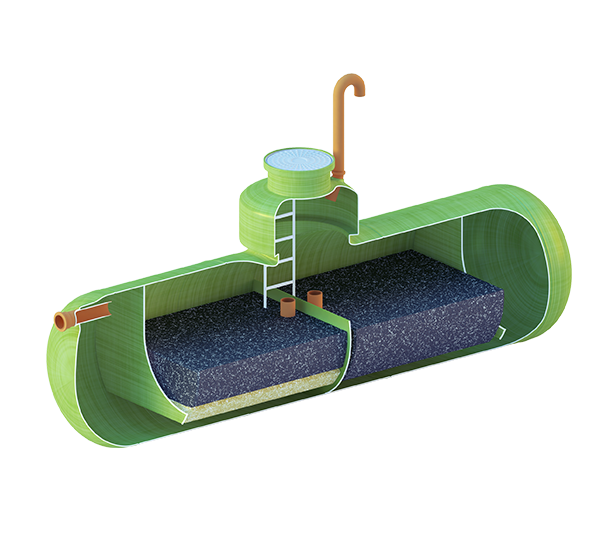

Active carbon filters are used in the final stage of treatment to neutralise residual oil particles, oil products, and suspended particles in the pre-treated stormwater.

Our active carbon filters contain chambers with hydrophobic sorbent and zeolite to effectively neutralise oil products and suspended particles.

| In | out | |

|---|---|---|

| Suspended solids | < 300 mg/l | < 3 mg/l |

| Oil | < 75 mg/l | < 0,05 mg/l |

|

*In systems with grit chambers and oil separator of class 1 |

||

Efficiency

Efficient cleaning up in stormwater sewage systems of up to 3 mg/l in terms of suspended substances and up to 0.05 mg/l, in terms of oil products.

Maintenance

Once in 18 months.

How it works

Partially purified water from the oil/ fuel separator enters the active carbon filter, passing mineral filters and layers of sorbent. After purifying suspended particles in the lower level of zeolite, water is purified from oil product residues, passing through the layers of hydrophobic sorbent.

Maintance

During the first six months, it is recommended to check the active carbon filter every month, further on, once in 3 months. Sorbent is replaced according to a specified scheme and depending on the concentration of contaminants. If the active carbon filter has been chosen correctly, sorbent needs to be replaced once in 18 months.